Globalization has significantly changed business dynamics. Nowadays, companies must interact with different suppliers to manage the supply of products, services, and business operations.

That’s why there is an urgent need for effective supplier management to handle all aspects of the supply chain efficiently, avoiding common issues such as inadequate supplier selection, lack of monitoring and control, communication failures, delivery delays, and logistical problems.

In general, the purpose of supplier management is to identify the right suppliers and maximize value/relationships while reducing costs and risks, ensuring quality throughout the entire lifecycle.

In this article, we will cover everything about supplier management, including its importance, process, and benefits. Additionally, we will discuss how to modernize and automate supplier management with a BPM (Business Process Management) tool.

What is Supplier Management?

Supplier management is the administration of all business processes and activities involved throughout a supplier’s lifecycle. It includes but is not limited to identifying, qualifying, acquiring, and managing suppliers who facilitate business operations.

While supply management focuses on purchasing goods/services and other business-related resources, supplier management is about handling the relationship between the supplier and the business. Therefore, the primary goal of supplier management is to ensure that all aspects/contracts with suppliers are in place and properly managed to maintain smooth business operations and growth opportunities.

Strategies for Implementing Automated Supplier Management

The supplier management process consists of multiple ongoing steps and activities, such as:

- Supplier identification

- Supplier qualification

- Document management

- Supplier relationship management

- Documentation updates

- Supplier evaluation

To automate these processes, Qflow offers a ready-to-use, pre-designed template tailored for optimal supplier management. Let’s explore the details!

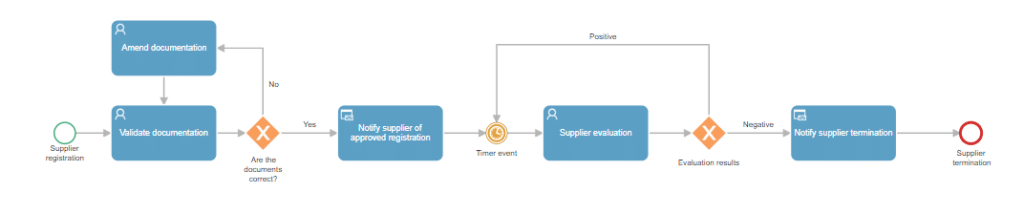

The process begins with supplier onboarding: once the ideal supplier is selected, a form is completed with the necessary information to initiate the business relationship, triggering management processes.

Next, a user reviews the submitted documentation. If any data is missing, the supplier is asked to correct it; if the documentation is correct, the supplier is notified that they can begin operations with the organization.

Even though, at this stage, the supplier is already operating for the company, the process doesn’t end there. The template includes an automatic evaluation at a defined interval (bimonthly, semiannual, annual, etc.), where KPIs related to quality, delivery times, and costs are analyzed. If the evaluation is positive, the period is renewed until the next review; however, if negative, the supplier is notified and removed.

If necessary, the process also notifies the supplier about the imminent expiration of their documentation, requesting the submission of updated documents for validation. Once received, a user reviews the documentation, and if correct, it is updated in the system, preventing delays due to missing required documents.

Main Challenges in Supplier Management

The fast-paced global economy requires companies to diversify their supplier base while maintaining an optimal purchasing management system. Additionally, emerging customer demands for high-quality products and timely deliveries are pushing companies to work with the best suppliers. This is why supplier management involves several challenges to overcome:

1. Supplier Selection and Evaluation

Choosing the right supplier remains the biggest challenge—identifying reliable suppliers who meet quality standards and essential company requirements while establishing the necessary criteria to evaluate their performance throughout the professional relationship.

2. Ensuring Supply Continuity

Reducing reliance on a single supplier is crucial to avoid disruptions. Having a contingency plan for potential supplier failures or external circumstances, such as regulatory changes or crises, will help mitigate their impact on business operations.

3. Regulatory Compliance

Identifying legal regulations, quality standards, and necessary certifications for a supplier to work with your organization and committing to periodic monitoring of compliance.

4. Cost Optimization

While cost reduction is the goal, efficiency should also consider maintaining quality. Therefore, negotiating competitive prices with suppliers without compromising service and considering possible fluctuations in raw material prices is essential.

5. Efficient Communication

Ensuring a transparent real-time flow of information between the organization and suppliers reduces errors and prevents potential conflicts before they occur.

Benefits of Optimizing Supplier Management with BPM

With an adequate supplier management system, a business can efficiently oversee and coordinate all its suppliers. This leads to proper onboarding, effective communication, simplified lifecycle management, and greater opportunities to identify improvement areas to reduce costs and enhance quality.

Supplier management is becoming a necessity rather than an option in today’s competitive landscape. Let’s take a closer look at some of its key benefits:

1. Cost Reduction and Quality Improvement

The supplier management process involves comprehensive identification and qualification of suppliers. This helps find the best supplier who excels in product/service quality, cost-effectiveness, fast deliveries, etc. As a result, you can obtain better-quality supplies at reduced costs.

2. Risk Reduction

Efficient supplier management minimizes risks related to supply chain disruptions, quality assurance, cost fluctuations, compliance issues, and similar concerns. Moreover, it also fosters mutual problem-solving and collaboration to support each other’s business growth.

3. Operational Efficiency Improvement

Supplier management is key to enhancing operational efficiency. First, it structures all essential elements of supplier management. Second, it facilitates regular supplier reviews, helping to identify deficiencies and areas for improvement. This way, greater operational efficiency can be achieved.

4. Better Visibility and Transparency

Supplier management provides greater visibility and transparency across the entire supply chain. You’ll receive timely updates on shipments and other supplier performance statistics. Additionally, open and clear communication enhances transparency, leading to better product/service quality and improved operational efficiency.

5. Price Volatility Reduction

Price fluctuations can significantly impact customers. However, effective supplier relationship management can mitigate this. For example, negotiating a fixed price or a gradual price increase in exchange for a minimum order size or a longer contract can help maintain strategic price management rather than dealing with unexpected volatility.

6. Stronger, Longer Supplier Relationships

Supplier management is essential for fostering strong supplier relationships. Effective collaboration builds trust and encourages innovation, allowing both parties to work together to grow each other’s business and maintain a solid, long-term partnership.

7. Higher Customer Satisfaction

When supplier management ensures high-quality products/services, lower costs, and timely deliveries, customer satisfaction increases. This satisfaction helps grow your business and benefits suppliers with more orders.

Impact of Automation on Supplier Management

Managing the numerous elements involved in supplier management can be overwhelming. This is where BPM comes into play. The Business Process Management (BPM) tool is a software solution that helps organizations model, execute, automate, and improve their processes. Specifically, regarding supplier management, a BPM tool provides a centralized and structured framework for organizing, automating, and optimizing supplier management activities.

Some ways a BPM tool can enhance supplier management include:

1. Process Automation

A BPM tool allows you to create workflows for various supplier management activities to standardize and automate them. For example, Qflow BPM can automate routine tasks such as invoice processing, order placement, and supplier onboarding. This helps save significant time, standardize activities, and reduce errors.

2. Improved Visibility and Control

A BPM tool provides centralized visibility and control over all supplier management activities. It helps track shipments, transactions, KPIs, and more. Additionally, it offers analytical data on aspects like delivery times, inventory levels, and supplier performance. This enhanced visibility leads to greater operational efficiency and helps identify gaps.

3. Facilitating Collaboration

A BPM tool not only improves operational efficiency but also enhances effective collaboration with suppliers. It serves as a centralized platform where businesses and suppliers can collaborate on different activities, such as document access/exchange and viewing current statistics. For example, if an issue arises regarding a delayed shipment, Qflow BPM can automatically notify the relevant parties, simplifying collaboration and strengthening relationships.

Conclusion

Since almost all businesses now involve multiple suppliers, supplier management is becoming essential for companies. It provides a structured way to handle all key supplier-related activities, leading to cost reduction, quality improvement, and many other benefits.

Moreover, by implementing a tool like Qflow for supplier management, you can gain additional advantages such as automated processes, enhanced visibility, and effective collaboration.